How Predictive Maintenance AI Helps Factories Run Smarter and Reduce Downtime

Imagine the Problem

Picture this: a factory machine suddenly stops working. Production stops, orders get delayed, and money is lost.

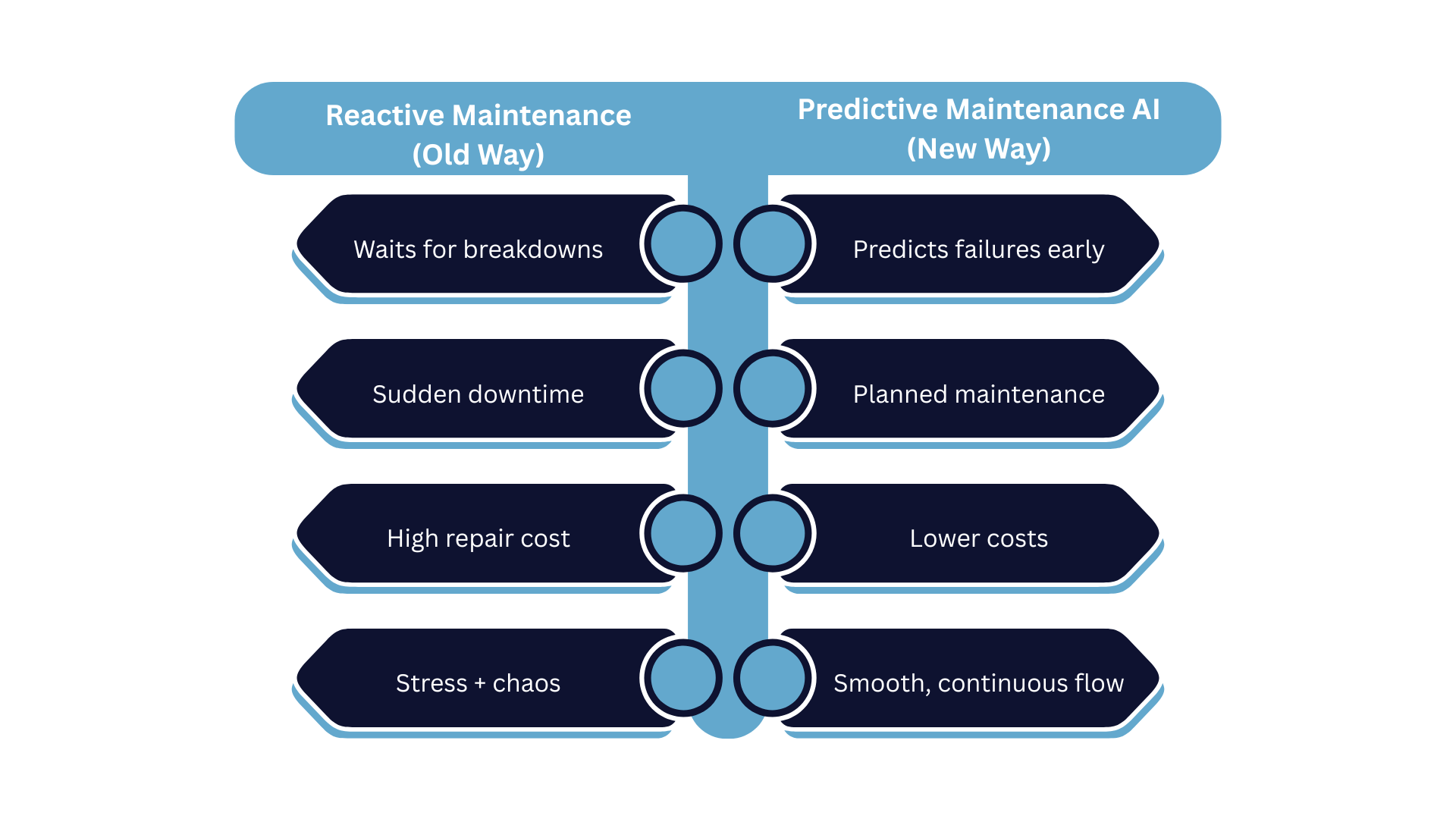

For years, factories only fixed problems after they happened. But now, predictive maintenance AI is changing that. It can spot problems before they happen, so factories don’t have to wait for breakdowns.

What is Predictive Maintenance AI?

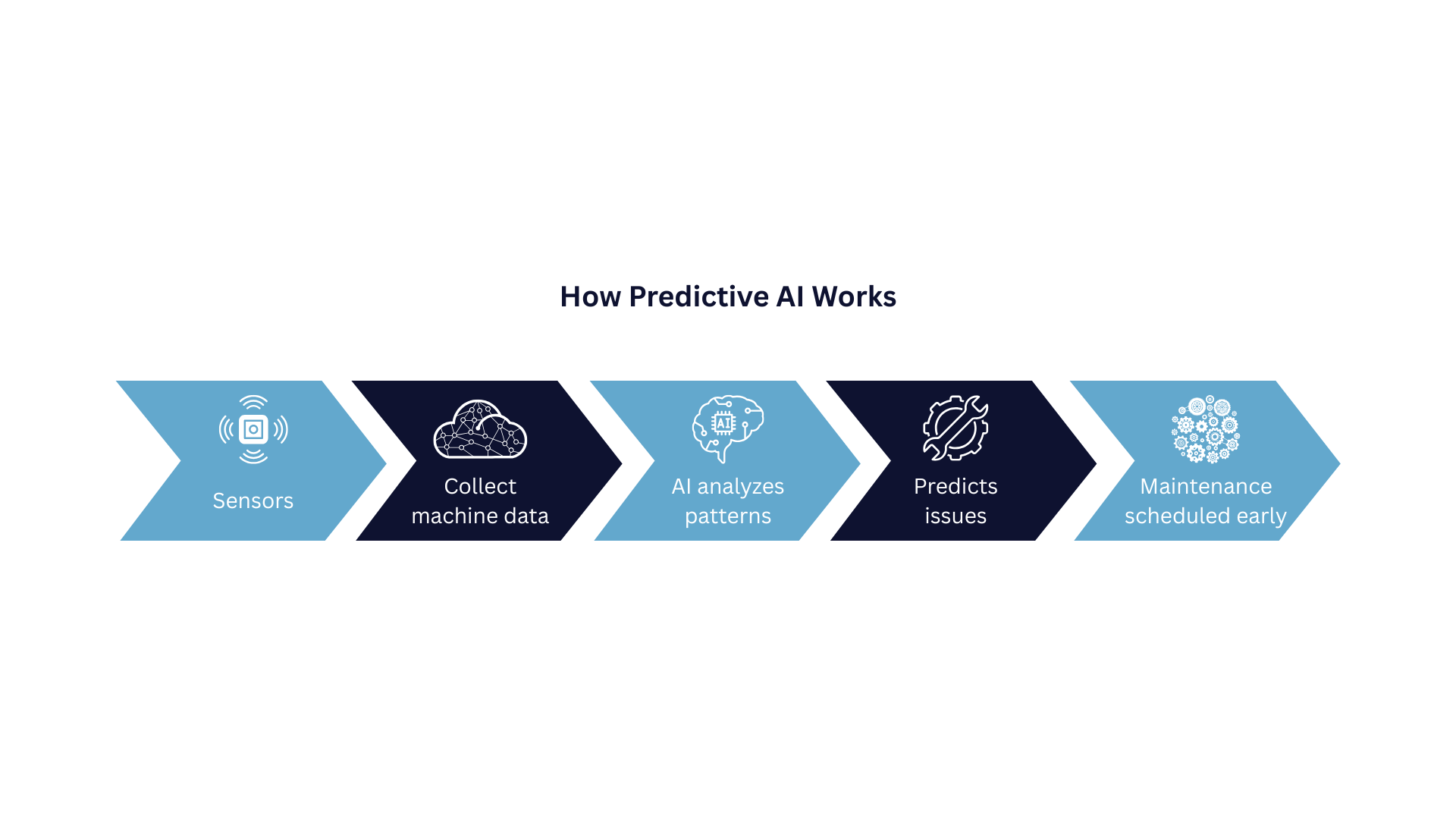

Predictive maintenance AI is a smart system that watches machines, like checking temperature, vibrations, or how much they’re used and predicts when a problem might occur.

Think of it like a warning light on your car. Instead of breaking down on the highway, you get a signal to fix it early. This helps factories plan repairs ahead of time and avoid costly stops.

Real Lessons from Factories

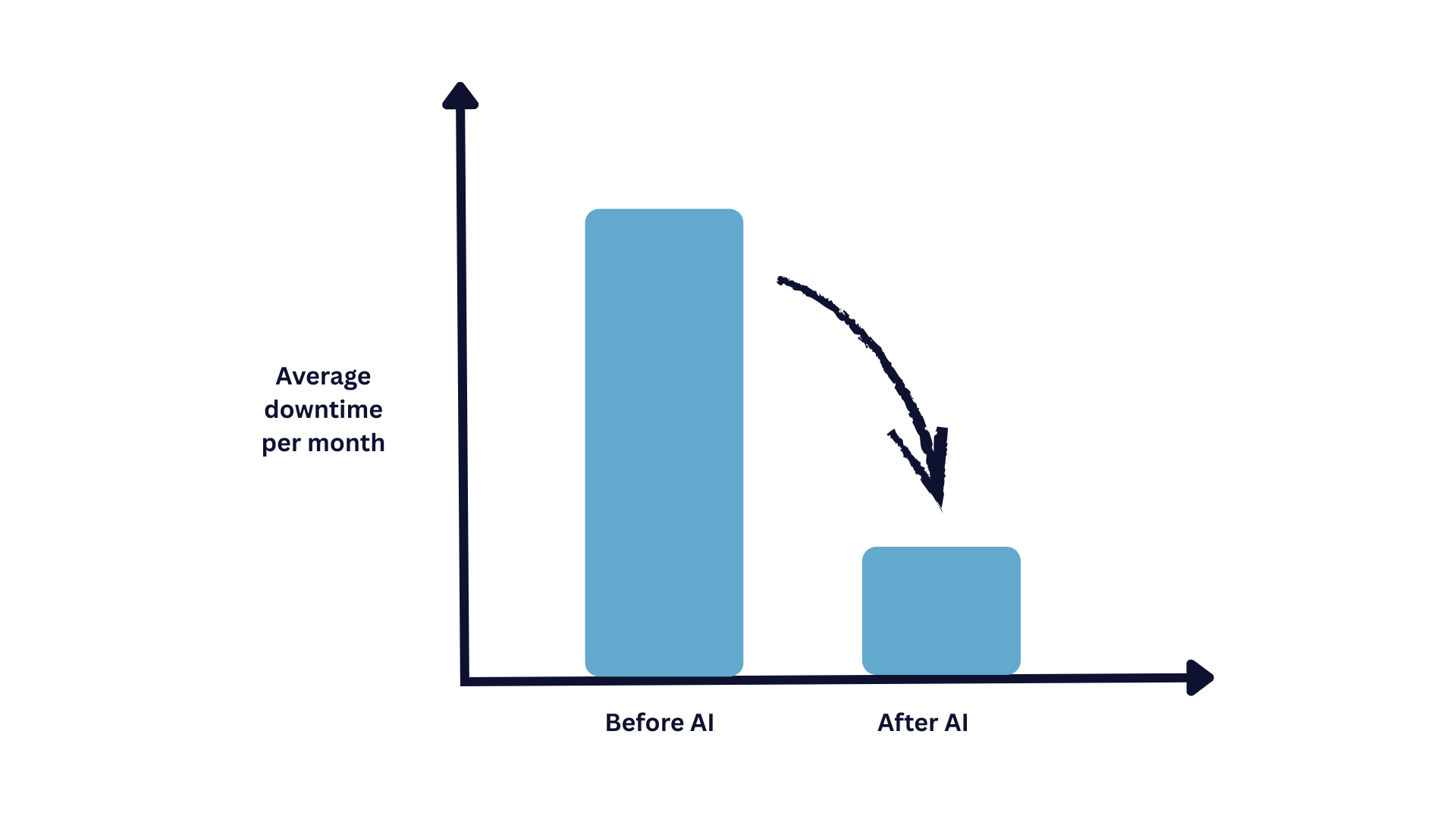

Factories using predictive AI are seeing real improvements:

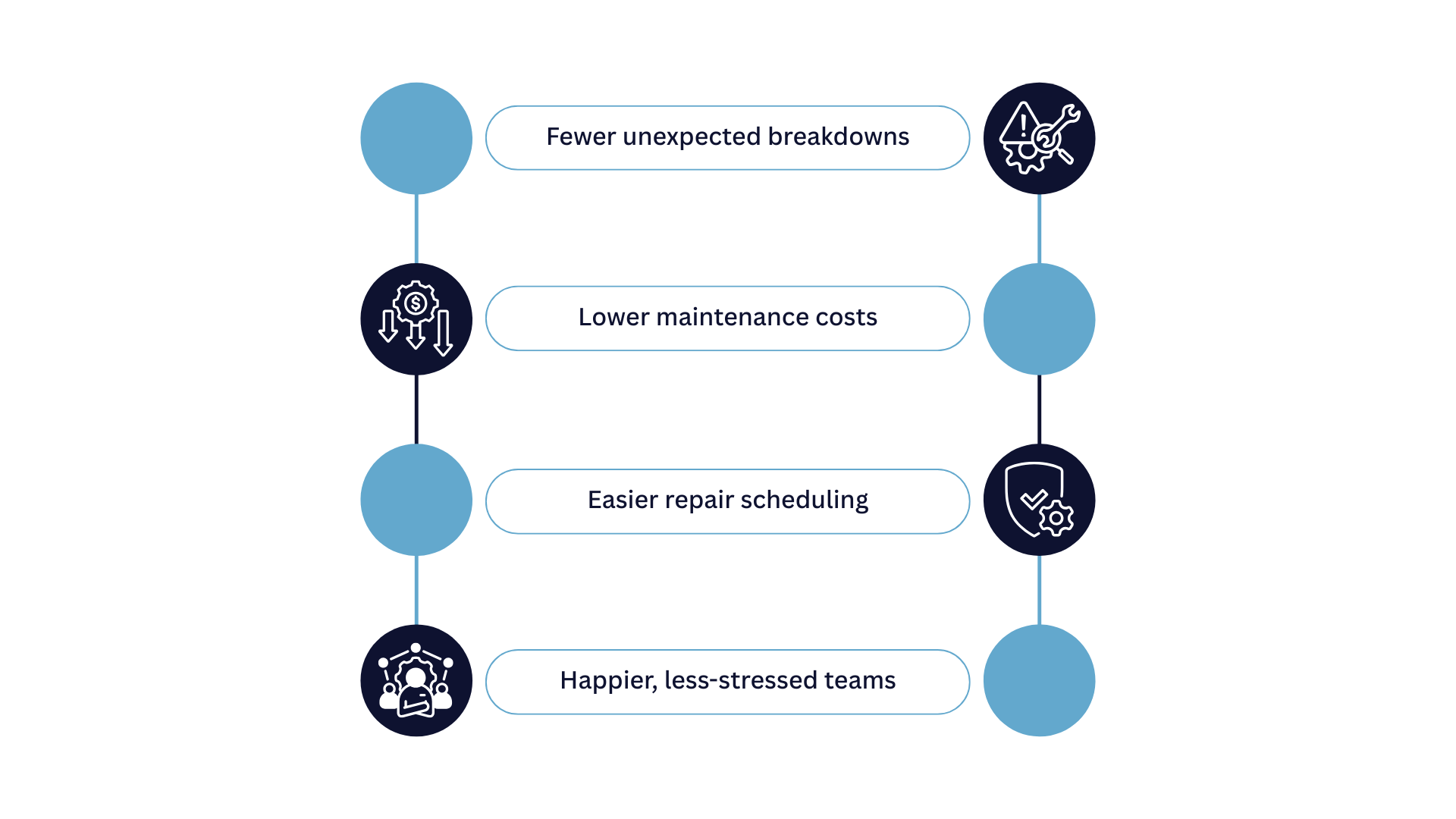

- Machines break down less often, so production keeps running

- Maintenance costs go down

- Teams can plan repairs better and faster

It’s not always easy. Factories need accurate data, staff who trust the AI, and smooth integration with older machines. The ones that succeed start small, learn quickly, and grow steadily.

Why This Matters

Predictive AI isn’t just a tool, it gives factories a real advantage. They move from reacting to problems to preventing them. This saves money, keeps work on track, and helps factories stay ahead of competitors.

From an insider’s view, the factories that win are the ones who combine AI with smart planning and experienced staff. Start small, see results, and scale wisely.

Final Thought

Predictive AI isn’t just a tool, it’s a strategic advantage. Factories that embrace it move from reacting to problems to preventing them, saving money and staying ahead of the curve.

At SeeWise.ai, we help factories turn these insights into action. Our AI-driven solutions are designed to reduce downtime, improve safety, and boost efficiency.

Want to see how predictive AI can make your factory smarter? Explore our solutions here.