How AI Is Transforming Galvanizing: From Manual Checks to Smart Automation

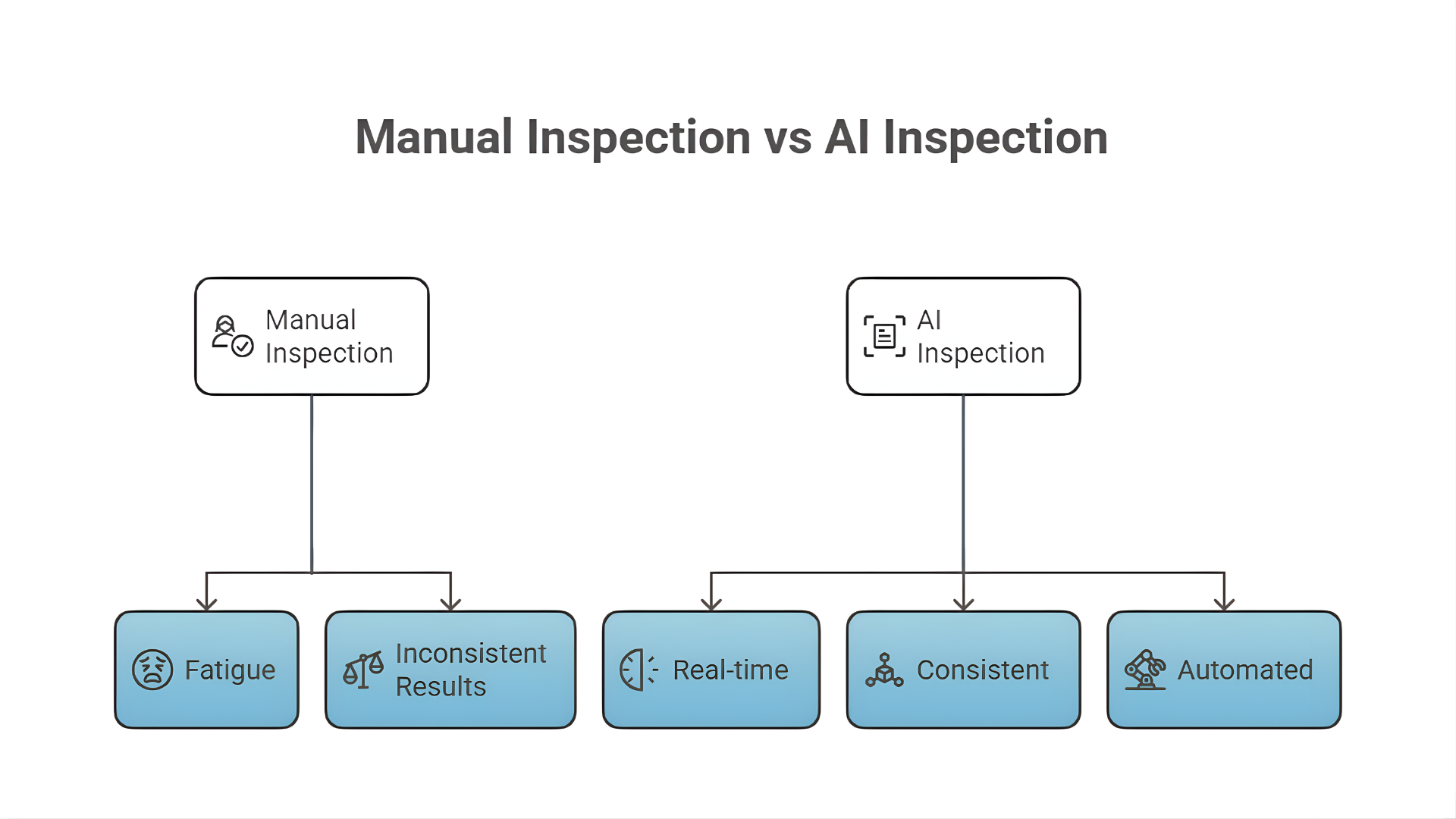

For decades, the galvanizing industry has relied on people to inspect and control every step of coating steel with zinc. This hands-on process protects our bridges, buildings, and machinery from rust - but it also comes with challenges. Human inspection can be slow, inconsistent, and prone to error, especially in harsh factory conditions.

Now, Artificial Intelligence (AI) and computer vision are rewriting that story. By turning cameras into intelligent eyes, AI is helping galvanizing plants move from manual inspection to smart, automated quality control.

The Problem with Manual Inspection

In galvanizing, each steel part is dipped into molten zinc to create a protective layer. After coating, workers visually check for defects like uneven coating, bare spots, or zinc buildup. But this is far from easy:

- Every inspector sees things differently.

- Long shifts cause fatigue and missed defects.

- Rework and scrap add up, cutting into profits.

Simply put, manual inspection can’t keep up with the demand for perfect, consistent coating in modern production lines.

How AI Changes the Game

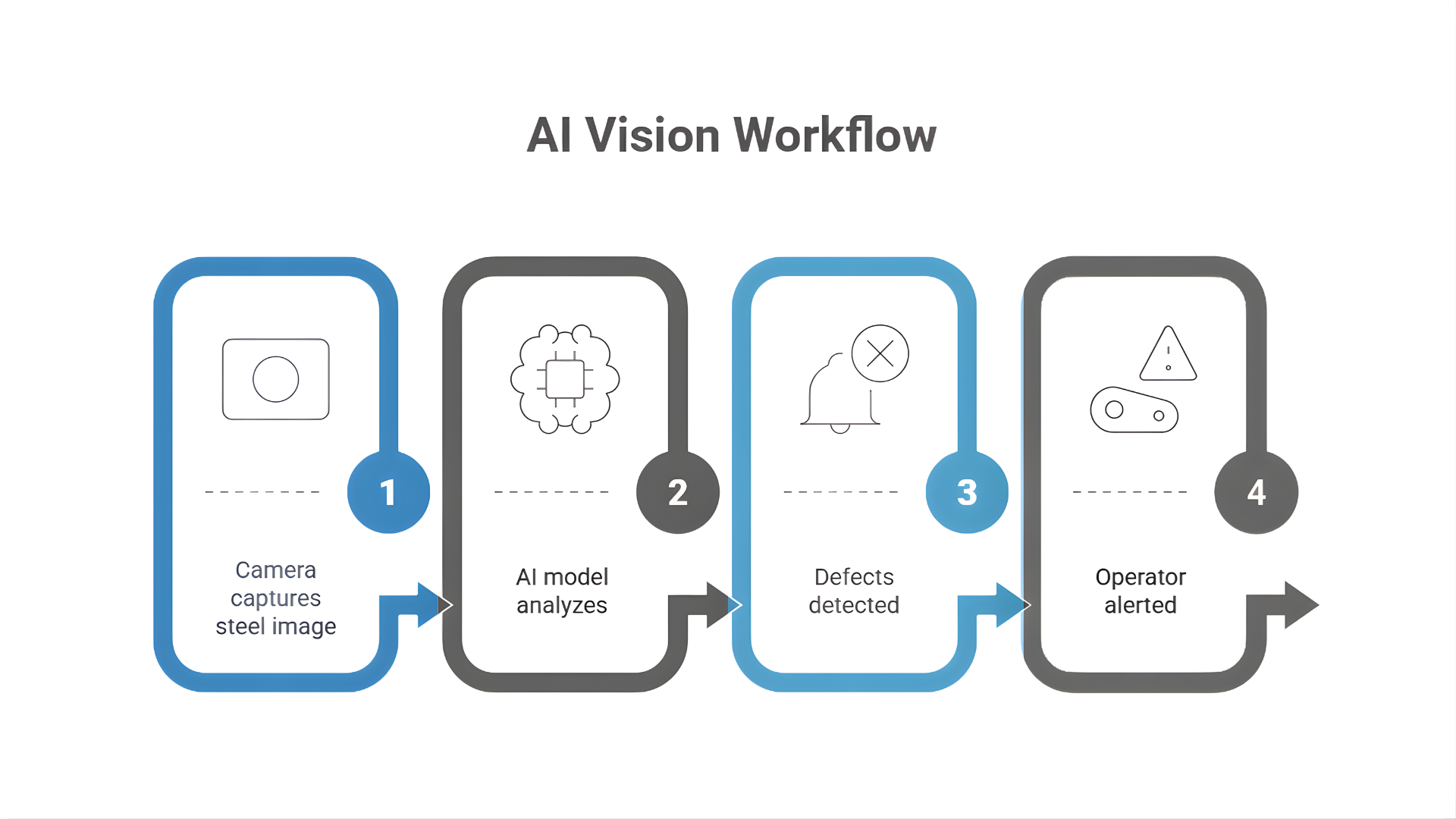

AI with computer vision acts like a digital quality inspector. High-speed cameras capture each piece of steel as it leaves the zinc bath. The AI instantly scans the images to spot even the smallest irregularities - things that might escape the human eye.

For instance, if it spots a dull patch or uneven shine, the system flags it instantly. The operator gets real-time feedback and can take action immediately, instead of finding out later that a batch didn’t meet standards.

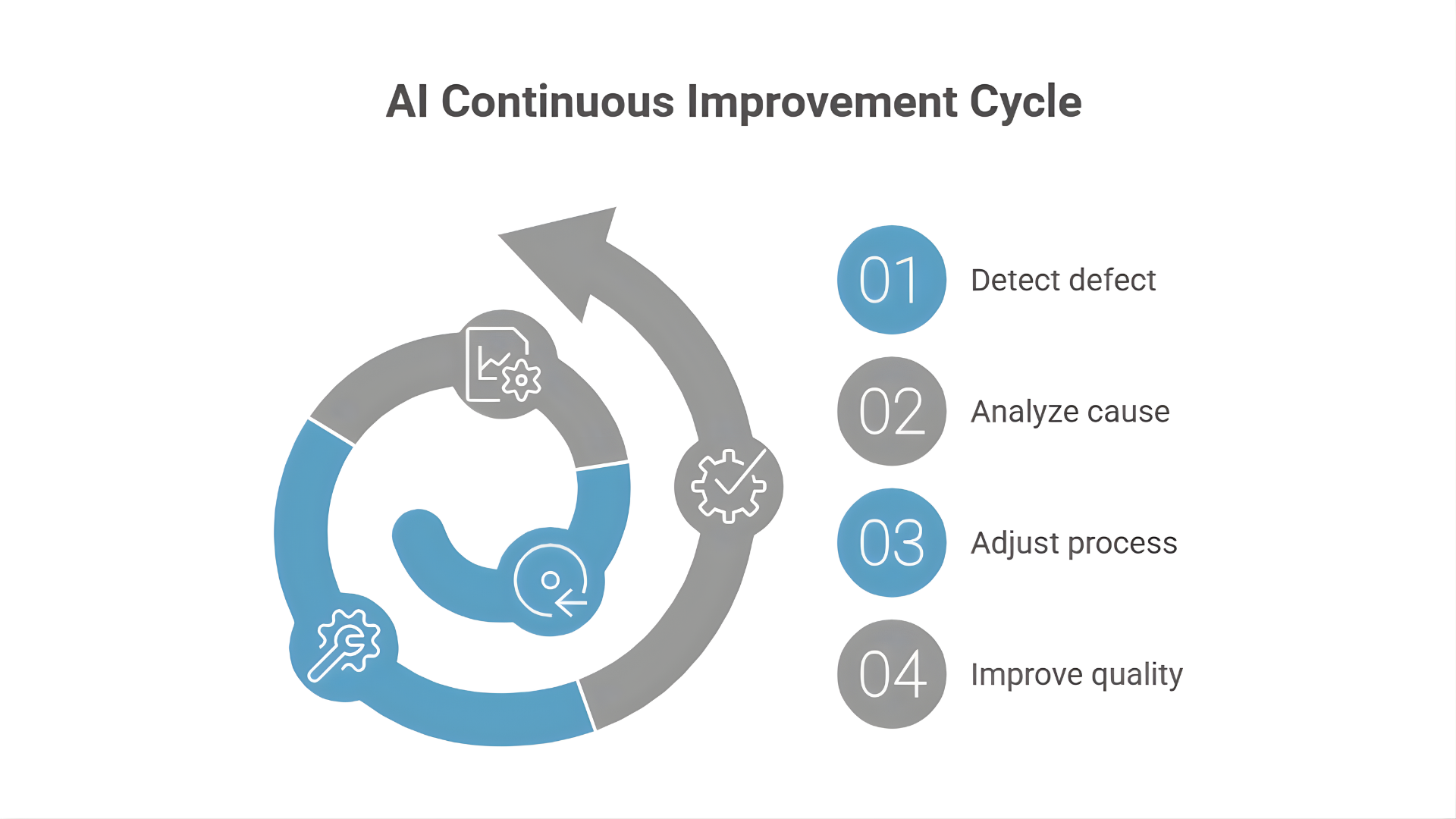

That’s not all - AI also learns patterns over time. It starts to understand how dipping speed, temperature, or zinc flow affect coating quality, allowing it to suggest the best settings automatically.

Smarter, Faster, and More Reliable

AI doesn’t just inspect; it helps control and optimize the process. When a recurring defect appears, the system connects the dots and adjusts parameters like withdrawal rate or bath temperature to fix the root cause.

It can even predict when the zinc bath needs maintenance. By analyzing visual signs of dross or turbulence, AI can alert teams before a breakdown happens. That means less downtime and smoother operations overall.

The Result: A Stronger, More Efficient Process

By adopting AI-based automation, galvanizing plants gain:

- Consistent quality across every batch.

- Faster inspection with real-time alerts.

- Lower rework and maintenance costs.

This shift doesn’t replace human expertise - it enhances it. Workers spend less time checking for mistakes and more time improving processes.

With SeeWise.AI, manufacturers can bring this level of intelligent automation to their galvanizing lines. Our Vision AI solutions detect surface defects, monitor process variations, and deliver real-time insights that drive accuracy and productivity - without disrupting existing workflows.

AI is helping galvanize the move from reactive fixes to proactive, data-driven decisions - and SeeWise.AI is bringing that future to life today.